The first step in powder coating surface preparation is an alkaline wash to remove contaminants like liquids, dust and soil.

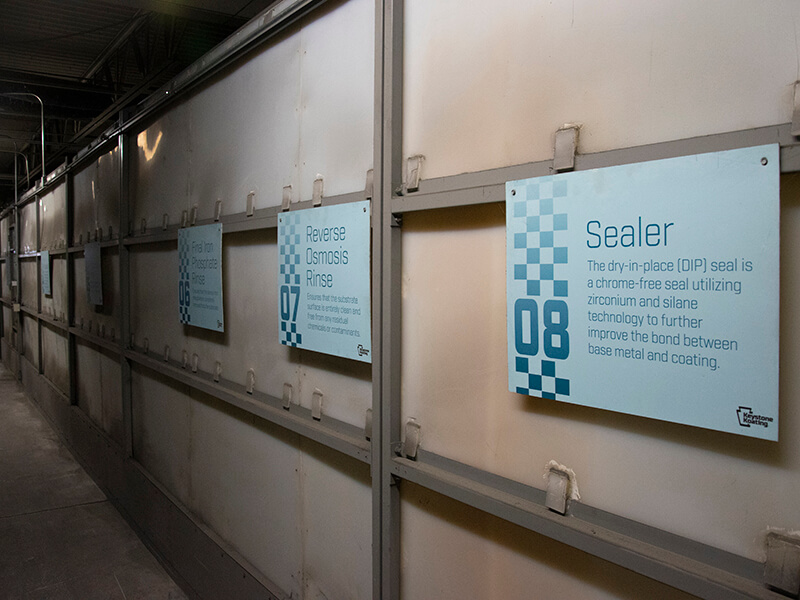

Powder coating pretreatment cleans and seals products before powder application. Pretreatment is incredibly effective at removing oils, greases and other impurities. In many cases, powder coating pretreatment can eliminate the need for additional abrasives blasting, saving both time and money. Through different stages of the process, pretreatment seals products for extra protection and improved adhesion between the metal surface and the primer or powder coat.