Blasting

Our blasting process removes previous powder coating, rust, corrosion, buildup and other residues that could prohibit an even finish.

Explore Sandblasting ServicesWhat are you looking for?

If your industrial project calls for a resilient, long-lasting and visually appealing finish, powder coating is a cost-effective and durable solution. Read on to learn more about our industrial powder coating services in Pennsylvania, typical applications and how it’s different from standard, nonindustrial coatings.

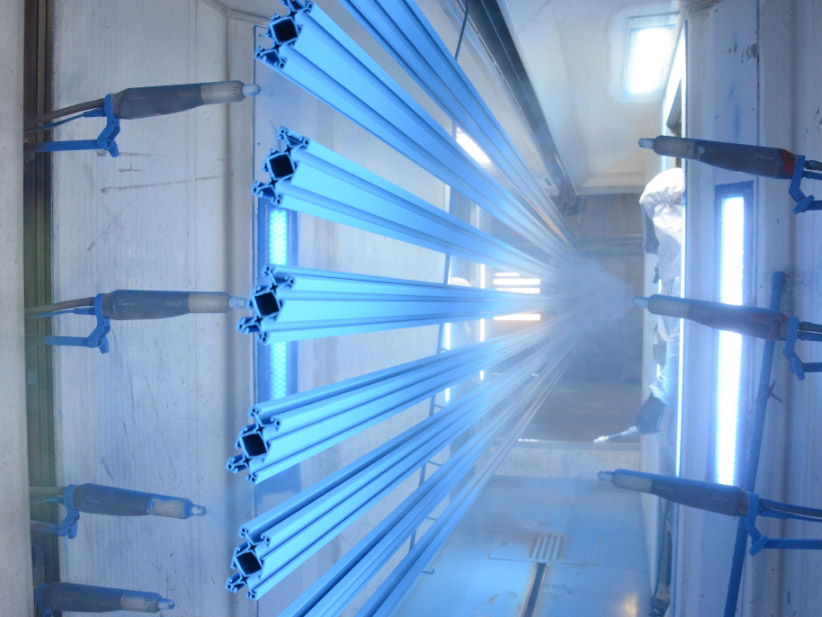

Industrial powder coating is a large-scale, high-volume coating for commercial needs. The powder coating process involves applying a layer substance made of fine, pigmented particles and polymer resin to specific types of plastic or metal. Unlike paint, there are no liquid solvents present. The item then cures in a high-heat oven, resulting in a nearly impenetrable film or coating, which is thick or thin, depending on the application process.

Two types of powder coating processes include:

Both processes require high temperatures and may take anywhere from several minutes to several hours.

If an item has a lot of rust, scaling or dirt, you may need to blast it with a highly pressurized liquid or compressed air inside a blasting room to clean it thoroughly and promote even application. Once the item has finished curing and cooling — you know it’s ready to go if it has set enough that it will no longer remelt if heated again — it’s ready for further processing, packaging or shipping.

Typical industrial powder coating applications include:

|

|

|

Powder-coated items can withstand daily use and years of wear and tear without touch-ups or replacements, ideal for high-traffic placement and applications. Compared to paint, industrial powder coating offers far more durability and added resistance to:

Because industrial powder coating provides such a durable finish, you’re ensuring a high-quality finished product and, ultimately, an investment that pays for itself.

Get a QuotePowder coating affords endless color options, finishes, textures, patterns and styles, whether you’re working toward a uniform look for multiple automotive parts or creating a one-of-a-kind piece for your architectural project. Colors range across the spectrum, including matte, glossy, high-gloss, pearlized, neon or sparkling finishes. Skilled applicators can even use stenciling techniques to create designs and artwork on your metal piece.

This level of customization and flexibility makes industrial powder coating the best option for projects that must meet highly specific standards or legal requirements, like road signage.

Get a QuoteUp to 98% of powder-coated items are ready for completion after only one coat, making it ideal for quick turnaround projects and simplified production processes. The fewer required applications, the faster you can create the final product and use it for your project or ship it to your client. It also means the curing oven is on for less time, resulting in lower heating and production costs.

Though professional industrial powder coating does require training and supervision, it’s reasonably straightforward to learn and apply for the appropriate permits. If your specifications for the final product change, you can adjust quickly and with minimal wasted resources.

Get a QuotePowder coating contains no volatile organic compounds, which the EPA defines as emitted gases containing various chemicals that can have adverse health effects on humans and animals. Possible side effects from prolonged VOC exposure may include:

|

|

Since VOCs contribute to air pollution, the EPA has strict regulations in place for their use outdoors. Because powder coating doesn’t emit these harmful toxins, it’s far safer for you and the environment, and it’s easier to dispose of leftover materials once you finish your project. The single-coat application process also conserves resources, minimizes oven use and saves time, which can help contribute to a more sustainable building or project plan. In some situations, you even catch and reuse powder coating overspray and put it back into the hopper for recirculation.

Get a Quote