Updated June 24, 2024. Originally published April 15, 2021.

Industrial manufacturers, automakers and more rely on powder coating to improve the durability and appearance of metal products. No two powder coating jobs are alike, and there are a number of customization options to choose from. One option is to make adjustments to the texture of the metal surfaces via powder coating.

Choosing the Right Powder Coating Texture for Your Project

The goal of powder coating metals is to increase durability and manipulate the appearance of a surface. Choosing a coating texture helps ensure that the end product meets design expectations. Coating textures range in durability, so you may select one based on the product’s application. Different textures also create distinct looks, from an antique appearance to a more modern appeal.

The available powder coating texture options may vary depending on who performs the coating, but here are a few of the most common ones.

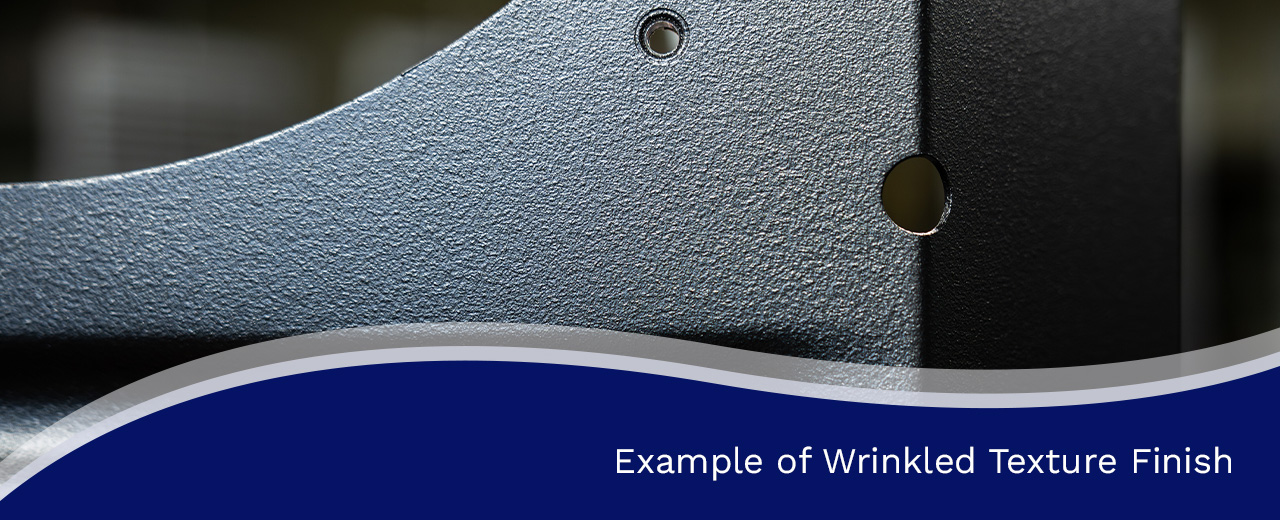

Wrinkled Textures

Wrinkled powder coating textures have minimal shine (gloss). The surface of the coated product feels similar to sand and stands strong against wear and tear. It’s common to find wrinkled powder coating textures in industrial settings where surfaces must resist scratches from sharp tools.

This type of powder coating feels gritty and features tight cracks throughout. A wrinkled texture calls for the use of urethanes and offers exceptional weathering and corrosion resistance. They can hide the surface of a metal with a powder coating that adds some visual depth.

Within the category of wrinkled textures, you can choose a splatter texture. This option creates a high-end look and feel with color variations that resemble paint splatters.

River Vein Textures

The technique used in river vein textures leaves small water-like channels across a material. This texture creates a distinctive antique look due to the darker color in the veins, contrasted with a metallic color on the surface.

It takes an experienced professional to apply a river vein texture because spraying epoxies or polyesters too thin can lead to uneven results. Companies add this texture to original products for a unique look with the choice of a single or two-tone color configuration. Incorporate a river vein powder coat texture for indoor applications, including electrical housings and furniture.

River vein textures can also be applied using super durable polyester powder, which provides excellent outdoor durability.

Hammer-Tone Textures

A hammer-tone texture is similar to the surface of a golf ball or the skin of an orange. Hammer-tone powder coating textures are ideal if a product requires a thick exterior coating that is resistant to minor impacts, scratches and chips. This texture gives products a modern appearance and is well-suited for outdoor furniture, lighting fixtures and architectural applications.

Sand Texture

Sand texture powder coating has a gritty finish, much like sandpaper. This coating texture makes materials more resistant to friction, which can be helpful in certain applications. This texture is achieved by adding material during the coating process. A thinner color coat creates a rougher texture, while a thicker coat lessens the grit. This texture has several applications, including sports equipment, outdoor furniture and nonslip surfaces.

Metallic Powder Coating

This coating texture uses flecks of aluminum or mica in the powder to create a pearlescent or metallic appearance. Depending on the colors and sizes of metallic flakes, you might get a glittery look or a more subtle sparkle. Metallic powder coatings have a smooth texture. This coating texture adds visual appeal to products.

Metallic powder coatings suit various applications, including coating automotive parts or outdoor furniture. These coatings can also add visual appeal and protection in industrial settings.

Other Powder Coating Factors to Consider

It’s important to consider the applications of an original product when deciding on a powder coating solution. Your powder coating texture will influence many design factors. Here are a few additional factors to consider when choosing powder coat texture types.

Color

Professional powder coating services enable you to choose from a wide range of stock colors for textures. Color options include black, white, gray, red, yellow, orange, green and blue. At Keystone Koating, you can also create your own custom color sample to match your exact vision.

Gloss

Thin surface textures give you the opportunity to add gloss effects. Decide whether a matte (solid), low gloss, medium gloss or high gloss (reflective) surface is appropriate for your product. Matte gloss can hide surface imperfections better but is more challenging to clean. A high gloss level means easier cleaning but might show imperfections more easily.

Environment

While texture influences visual appearance, it also changes how the coating performs in different environments. When choosing a powder coating, consider factors like abrasion, extreme temperatures and chemicals. Some textures work well for hiding minor surface imperfections, while others offer excellent scratch resistance.

Substrate Material

Before choosing colors, textures and other coating factors, you should determine the type of material beneath the coating. The substrate material may impact various stages of the powder coating process, including the coating texture you choose.

Learn More About Powder Coating Textures at Keystone Koating

Since 1986, Keystone Koating has been serving clients in diverse markets with innovative powder coating services. We create tailored solutions for products made of aluminum, zinc alloys, iron and steel. Our central Pennsylvania facilities allow us to take on jobs of all sizes and provide impressive turnaround times. We have the expertise to apply various powder coating textures that meet your requirements. We’ll work with you to find a texture that provides the desired look while meeting your durability requirements.

Have questions about the powder coating textures we offer? Complete our contact form to get in touch or request a quote for our services today.