Updated June 24, 2024. Originally published June 16, 2020.

A durable finish coat is essential for protecting metal products from damage and wear both indoors and outdoors. If you manufacture metal products in any volume, you need to apply the right surface coating to meet the demands of your applications and get the final appearance you want to achieve. In today’s marketplace, two of the most popular options for protecting metal surfaces are powder coating and hot-dip galvanizing. While these finishes are comparable with one another, they’re far from the same, and each one produces different outcomes.

Table of Contents

- What Is Powder Coating

- What Is Galvanizing?

- Powder Coating vs. Galvanized Steel Finishes

- What Is the Difference Between Galvanized and Powder Coated Steel?

- Can Powder Coating Be Applied to Galvanized Steel?

- Does Galvanized or Powder Coated Steel Rust?

- Costs of Powder Coating vs. Galvanizing

- Get a Quote for Custom Powder Coating

Defining Powder Coating

Powder coating is a versatile industrial metal coating popular for use across multiple industries. These coatings are attractive and provide exceptional durability for interior and exterior purposes. Powder coating is a multi-step process that ensures surfaces are cleaned and prepared for a smooth application and strong bond. The powder coating process uses a combination of positive and negative electric charges, attracting powders to each bit of exposed metal surface and holding them there until curing is complete.

What Is Galvanizing?

Galvanizing is a finish common for marine applications and construction materials. This process involves applying a layer of zinc onto a surface for protection. During galvanization, metal products typically go through several chemical baths for preparation. Following prep, items go into a tub of molten zinc and hang to dry while cooling. Other application methods also exist. Unlike powder coating, zinc coatings are available in only one color — silver — which can create severe limitations if you want to add visual appeal to your items.

Powder Coating vs. Galvanized Steel Finishes

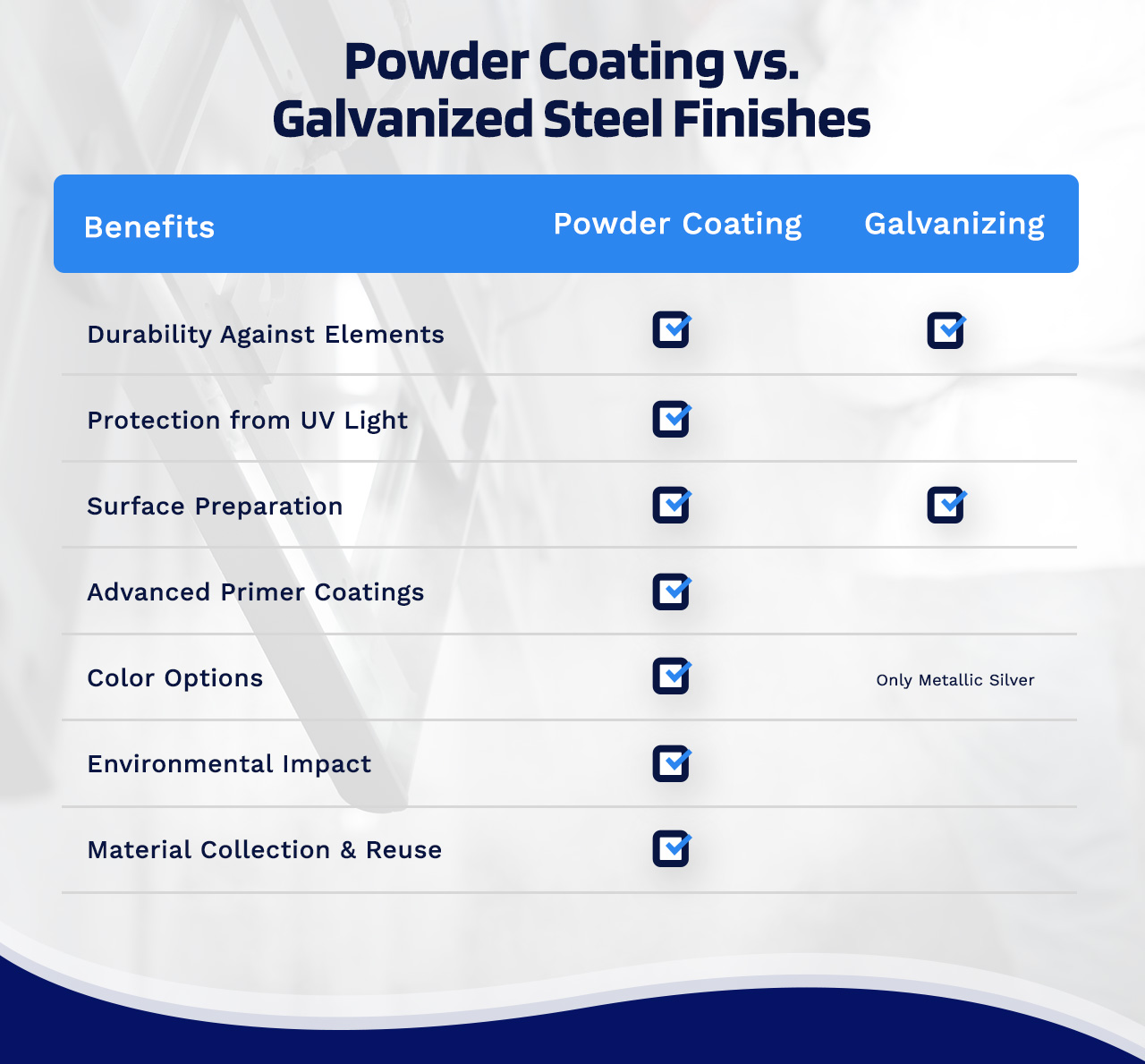

For any application, powder coating offers distinct advantages over galvanizing. While galvanizing has a reputation for durability against the elements, today’s powder coatings provide a worthy match. Options like Super Durable Powders offer even more protection from the sun and ultraviolet light.

Even though both processes involve steps to prepare surfaces for coatings, they have different results. During galvanizing, baths remove grease and oxides, but products covered in slag, thick residues, wax and other materials will often require surface preparation by another provider. In the powder coating process, a combination of blasting and pretreatment removes all residues for ideal application. At Keystone Koating, we can also apply advanced primer coatings for added protection from the elements.

While galvanizing comes in metallic silver, powder coatings come in a wide variety of stock colors. When you partner with a professional coatings provider, you can also take advantage of color-matching services to complement any interior or exterior space. And finally, a clear benefit of powder coating is how environmentally friendly the process is from preparation to completion. Powder coating maximizes material collection and re-use to produce virtually no waste or emissions.

What Is the Difference Between Galvanized and Powder Coated Steel?

In addition to the different materials and application processes, the most significant difference between galvanized and powder coated finishes is how they offer protection. Galvanized coatings absorb corrosive materials to protect the product from rust, preventing the corrosion from reaching the item. In contrast, powder coatings form a protective layer around the item so corrosive materials do not penetrate the barrier.

Both methods are effective — galvanizing is excellent for outdoor equipment or products, while powder coating is often more flexible and suitable for products that will stay inside.

Can Powder Coating Be Applied to Galvanized Steel?

Yes, we can apply a powder coat over galvanized steel to create a high-grade architectural finish. This combination provides exceptional resistance to the elements, but galvanized products require surface preparation to ensure a quality and lasting coat. Before applying powder coating to any galvanized steel products, we recommend blasting and pretreatment. Blasting removes defects to create a smooth surface, and pretreatment cleans products and enhances them for greater adhesion with your choice of powder.

Does Galvanized or Powder Coated Steel Rust?

Galvanized steel can rust, but it occurs extremely slowly. Powder coated steel is even less likely to rust.

Metals rust and corrode because their chemical components react with oxygen molecules. When galvanizing steel, the zinc coating prevents rust and corrosion from happening quickly because the coating forms an oxide layer, preventing oxygen from reaching the steel. While galvanized steel is not likely to rust, proactive action is still required to prevent it.

Galvanized steel works best in dry environments, away from moisture. While it can handle getting wet occasionally, exposing galvanized steel to moisture can make it more susceptible to rust. The temperature also affects the zinc. Galvanized steel can withstand temperatures up to 480 degrees Fahrenheit (250 degrees Celsius), but exposure to higher temperatures can make the zinc coating start to peel.

Compared to galvanized steel, powder coated steel virtually does not rust. The only way for the steel underneath the powder coating to rust is if it is damaged. Cracks in the coating could lead to oxygen or moisture seeping into the exposed steel, eventually leading to corrosion. While powder coatings are more corrosion-resistant, it is essential to be cautious of where the powder coated steel is located. Excess UV exposure can fade the powder coating, making it ineffective for rust protection.

Costs of Powder Coating vs. Galvanizing

Various factors affect the costs of powder coatings and galvanizing, including the coating’s thickness, the amount of material used, the labor required, and the price of the materials. Generally, powder coating is more cost-effective than galvanizing steel.

At Keystone Koating, we offer competitive pricing, and we can provide estimates for the products you need powder coating for. If you can’t visit us for an evaluation, complete our quote form and attach a drawing of your item with measurements.

Get a Quote for Custom Powder Coating

At Keystone Koating, we have more than 30 years of experience in the industry and two powder coating facilities ready to meet your needs. We offer competitive pricing on volume powder coating using quality powders and tailored processes for an optimal finish you can trust to last. To find out how we can help you get a durable finish with the exact look and feel you want, request a quote today.