Powder coating is an efficient and reliable way to coat metal, creating a durable, long-lasting and easy-to-maintain finish. However, improper application and poor powder mixes can create a subpar result. Manufacturers use a series of quality control tests according to industry best practices to ensure the highest possible standard of powder coating finish and give clients peace of mind.

Discover more about powder coating control testing, its importance and the various methods available to provide high-quality finishes.

What Is Powder Coating Quality Control Testing?

Quality control testing is the process of assessing the durability and integrity of powder coating finishes. Professional powder coaters use tests and performance criteria to determine the quality of powder coating. These tests cover the visual appearance and performance of finishes, such as color, gloss, adhesion, cure, flexibility, durability, chemical resistance, film thickness and corrosion resistance.

The most widely used standards for quality control testing in the powder coating industry are from ASTM International — formerly known as the American Society for Testing and Materials. The American Architectural Manufacturers Association — now the Fenestration and Glazing Industry Alliance — is another organization with industry guidelines for manufacturers in North America.

Companies can have confidence in their final products and ensure safety for users with these guidelines. Clients who choose businesses that comply with ASTM and AAMA standards know they will receive a high-quality and reliable service.

Why Is Proper Testing of Powder Coating Important?

Incorrectly applied powder coating finishes can have issues like uneven patches, sagging, bubbling, chalking and peeling. These cause the finish to degrade faster. Besides looking bad, poor powder coatings will fail to protect the metal underneath, causing rusting and corrosion. They also reduce performance and increase maintenance costs.

Manufacturers can troubleshoot and optimize their coating process with comprehensive and industry-compliant quality control testing to eliminate issues and create consistent and long-lasting outcomes every time. Testing also ensures businesses meet client expectations and comply with industry standards.

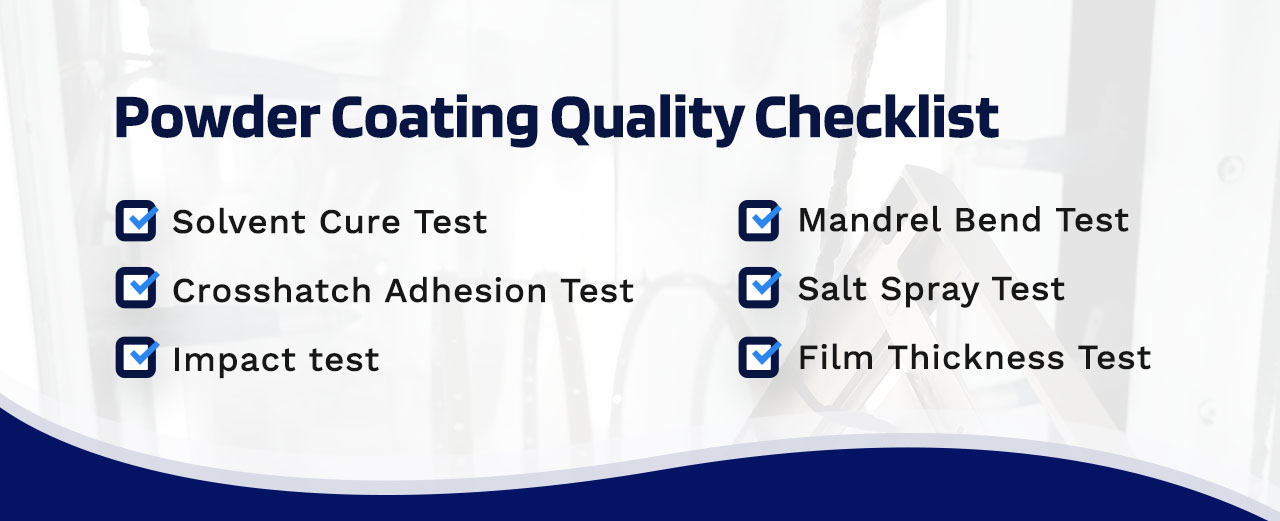

Powder Coating Quality Checklist

All powder coaters must test their finishes before they leave the facility to ensure their products stand up to the many environmental factors they encounter during use, such as humidity, temperature, water, sunlight and cleaning products.

We’ve compiled a list of the six most common powder coating quality tests below.

1. Solvent Cure Test

Powder coatings start as a powder that manufactures heat to create a durable, smooth and uniform finish. Professional powder coaters must use the correct temperature and cure time to achieve sufficient adhesion and maximum durability. You can perform a solvent cure test to test how well the powder coating has cured.

This test involves rubbing a cotton swab soaked in methyl ethyl ketone 25 times over the cured coating. Then, you can assess the cotton and coating for signs of degradation. A bit of rubbed-off color or gloss is fine, but the coating fails the test if too much coating rubs off or you see the metal underneath.

2. Crosshatch Adhesion Test

Adhesion refers to how well the powder coating attaches to a surface. Without proper adhesion, the coat will chip or peel off easily. The crosshatch adhesion test is a standard method for testing powder coating adhesion. This test is destructive, so you must create a separate panel for testing purposes.

To perform this test, use a specified crosshatch blade to make five parallel cuts through to the metal. Then, create five more cuts on top of and perpendicular to the first cuts. When you’ve formed a grid, apply special pressure-sensitive tape and pull it off at a 180-degree angle. The coating passes the test if nothing pulls off with the tape.

3. Impact test

You can perform the impact test to assess your powder coating’s adhesion and determine how well it holds up in high-stress environments.

This test is also destructive, so prepare a separate panel and place it into an impact testing machine. The machine will drop a weighted ball to form a depression in the panel. The finish should not crack or separate from the metal in the impact area.

4. Mandrel Bend Test

The mandrel bend test is another adhesion test for powder coating quality testing. It focuses more on the finish’s flexibility and how well it bends or elongates. Powder coating must have a specific elasticity level to prevent cracking or crazing during use.

You will need a specialized device to perform the mandrel bend test. Some devices have either multiple cylindrical mandrels or a single conical mandrel. Both will test the elasticity of the coating at various degrees, but the conical mandrel makes the process faster. Place the panel in the device and use it to bend the metal over onto itself. The bend area should not crack or separate from the surface at the desired bending angle.

5. Salt Spray Test

The metal surface will rust and corrode if water circumvents the powder coating barrier due to poor coating and curing. You can perform the salt spray test to test corrosion resistance for powder coating finishes.

The salt spray test involves cutting an X into a prepared powder-coated panel and placing it into a sealed fog or weather chamber. The chamber will mist a corrosive salt solution onto the panel for a set period, and you’ll need to take it out at specific intervals to record how far the coating creeps or moves away from the line you made. The coating passes the test if creepage is less than one-quarter inch.

6. Film Thickness Test

Powder coating thickness can vary according to the client’s requirements and the finished product’s purpose. Reaching the exact requirement is crucial for the coating’s performance and durability. You can use the film thickness test to assess your cured finish.

This test requires a piece of equipment called a film thickness meter or gauge. Press the meter to the coating surface to get a reading. Do this before and after curing in multiple places to get an average. The readings should fall within the allowed tolerance range.

Partner With Keystone Koating for Compliant Powder Coating

Keystone Koating is a full-service commercial and industrial powder coater in Pennsylvania with over 30 years of experience. We offer high-volume, customizable powder-coating services, focusing on precision and fast turnaround times. No matter your industry or needs, we’re confident we can provide a long-lasting finish.

We know how crucial quality testing is for powder coating, so we have a quality assurance testing lab. We employ various tests and procedures to ensure our finishes hold up under multiple conditions. We also test new systems as soon as they hit the market, allowing us to stay ahead of industry changes and deliver the best results. Additionally, we have all the relevant certifications and comply with AAMA and ASTM standards.

Get a quote within 48 hours by filling out our online form today.